Industrial Engineers skill assessment preparation and its future scope in Australia

Industrial Engineers skill assessment preparation and its future scope in Australia

If you are an industrial engineer planning to migrate to Australia for work, it is essential to know about the skill assessment process and the future scope of industrial engineering in Australia. In this article, we will discuss how to prepare for the industrial engineers skill assessment and the career opportunities available for industrial engineers in Australia.

Industrial engineering is a branch of engineering management concerned with how to make or do things better. It encompasses a variety of disciplines related to the production of industrial or consumer goods. This is an example of increasing efficiency, lowering production costs, improving quality control, ensuring employee health and safety, protecting the environment, and adhering to government regulations.

Industrial engineers work to reduce the waste of time, money, materials, energy, and other commodities by streamlining procedures and processes. This is accomplished by specifying, predicting, and evaluating the outcomes of processes and systems using specialized knowledge and skills. As a result, new processes and systems can be created, with business administration overlapping with areas such as production and manufacturing engineering, operations research, and systems development.

What is the significance of Industrial Engineering?

Table of Contents

Industrial engineering is required for both product producers and end-users. To make things more efficient, industrial engineers improve processes and designs. This benefits businesses by saving time, money, raw materials, energy, and manpower. On the other hand, industrial engineering is not solely concerned with profit margins; it also ensures the safety and quality of a product or process, which benefits both employees and end-users. Process analysis, design, prediction, and evaluation aid in removing roadblocks and creating higher-quality and more efficient processes and devices.

Industrial engineer’s work scenarios.

Industrial engineers work in various environments, including offices and the environments they are tasked with improving. This could include observing how a factory process works or investigating hospital workflows. This information can then be taken and analyzed on a computer to help solve problems.

Due to their diverse skill sets, industrial engineers can work in managerial and technical roles. Consulting and engineering, research and development, service industries, logistics, manufacturing, and trade are all places where they can be found.

Skills Assessment for Industrial Engineers

Australian companies hire Industrial Engineers based on their credentials and a thorough engineering study. Many people from Australia, India, China, Pakistan, the United Arab Emirates, Saudi Arabia, and others are attempting to relocate to Australia to further their education or pursue careers. However, in most professional engineering fields, there are only a few job openings in this country.

Engineers can use a Competency Demonstration Report to demonstrate their abilities when applying for an Australia Skilled Migration Visa. The Australian engineer, or EA, is responsible for reviewing all skills. There are a few requirements for engineering studies in Australia for immigration applications.

Engineers Australia requires you to write your own CDR for Industrial Engineering ANZSCO 233511 while demonstrating your technical knowledge and communication skills to demonstrate your flexibility and capabilities.

Industrial Engineer Task details

-

determining the functions and responsibilities of workers and work units, as well as identifying areas of duplication using functional statements, organizational charts, and project information

- Creating work measurement programs and analyzing work samples to develop labor utilization standards

- determining optimal worker and equipment efficiencies by analyzing workforce utilization, facility layout, operational data, and production schedules and costs

- designing mechanical equipment, machines, components, products, and plant and systems for manufacture, as well as developing manufacturing specifications and determining materials, equipment, piping, material flows, capacities, and plant and system layout.

- coordinating and managing project labor as well as material, plant, and equipment deliveries

- establishing engineering principles and safety regulations-based standards and policies for installation, modification, quality control, testing, inspection, and maintenance

-

Managing the maintenance of plant buildings and equipment, as well as design, survey, and maintenance requirements to ensure optimum performance is maintained.

CDR report format Industrial Engineers skill assessment

We guide applicants to prepare a CDR report maintaining the guidelines from Engineers Australia for a flawless and errorless CDR Report. Suppose you are an Industrial Engineer looking to relocate to Australia. In that case, you may submit a CDR Report for Industrial Engineer based on Engineers Australia’s Migration Skill Assessment. The ANZSCO Code for Industrial Engineer is 233513, featured on the Engineers Australia Skill Assessment list.

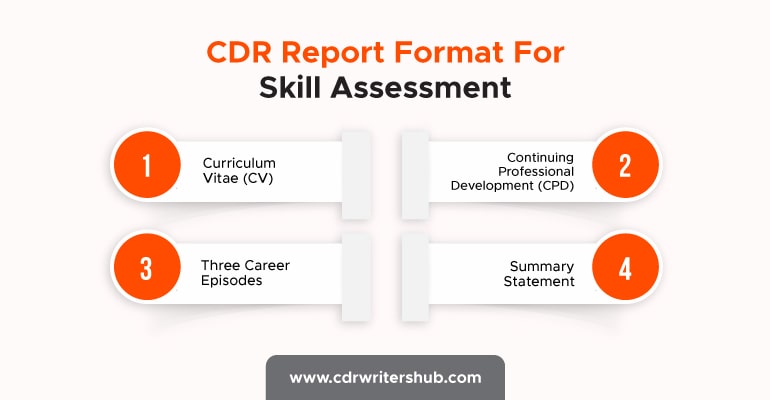

CDR Sample for Industrial Engineers includes curriculum vitae (CV), Continuing Professional Development (CPD), three career episodes (CE), and a summary statement. Listed below are the contents of a CDR report that will help you write a successful report.

- Curriculum vitae

- CPD (Continuous Professional Development) (CPD)

- Career Episodes

- Summary Statement

Future Scope for Industrial Engineers

Industrial engineering is still in demand, and students are interested in studying it. Industrial engineering offers a diverse range of career options, and it is expected to grow near future, which is much faster than many other occupations. Many industries are still focused on increasing efficiencies and lowering costs so that industrial engineers remain in demand. Traditionally, industrial engineering has focused on designing assembly line layouts and increasing worker productivity. The introduction of lean manufacturing systems has transposed the role of industrial engineers from identifying and avoiding waste to eliminating it.

Today’s industrial engineers map and analyze systems and processes in preparation for optimization using computer simulations and design. To improve processes and procedures in the future, such tools will likely be used alongside data science and machine learning. In industrial engineering, the Internet of Things is becoming an increasingly important part, and it appears that this trend will continue and expand in the future to connect employees, machines, materials, information, and more to create better practices.

CDRWritersHub, for your guidance

With the help of our skilled writers, you can write your report on-demand at CDRWritersHub. To ensure your evaluation is completed correctly, keep the EA criteria in mind and follow each guideline. Our team will assist you in the preparation of CDR reports, RPL reports, plagiarism detection and removal, EA feedback services, and other reports as needed.